Against the backdrop of the global rubber sheet market's robust expansion—projected to exceed $214.5 billion by 2030 with a 6.8% CAGR—Shenyang Longgreen Science & Technology Co., Ltd. has unveiled a revolutionary block rubber sheet release agent that redefines efficiency, sustainability, and performance in rubber manufacturing. As demand for high-quality rubber sheets surges across automotive, industrial, and construction sectors, this advanced block rubber sheet release agent addresses longstanding industry pain points, solidifying the company’s position as a driver of innovation in the global rubber chemicals landscape.

The Critical Role of Bulk Rubber Sheet Mold Release Agent in Modern Manufacturing

In rubber sheet production, the ability to achieve seamless mold separation directly impacts product quality, production efficiency, and operational costs. Traditional release agents often struggle with inconsistent performance, high adhesion rates, frequent reapplication needs, and non-compliance with evolving environmental regulations—challenges that the new solution from Shenyang Longgreen is engineered to solve.

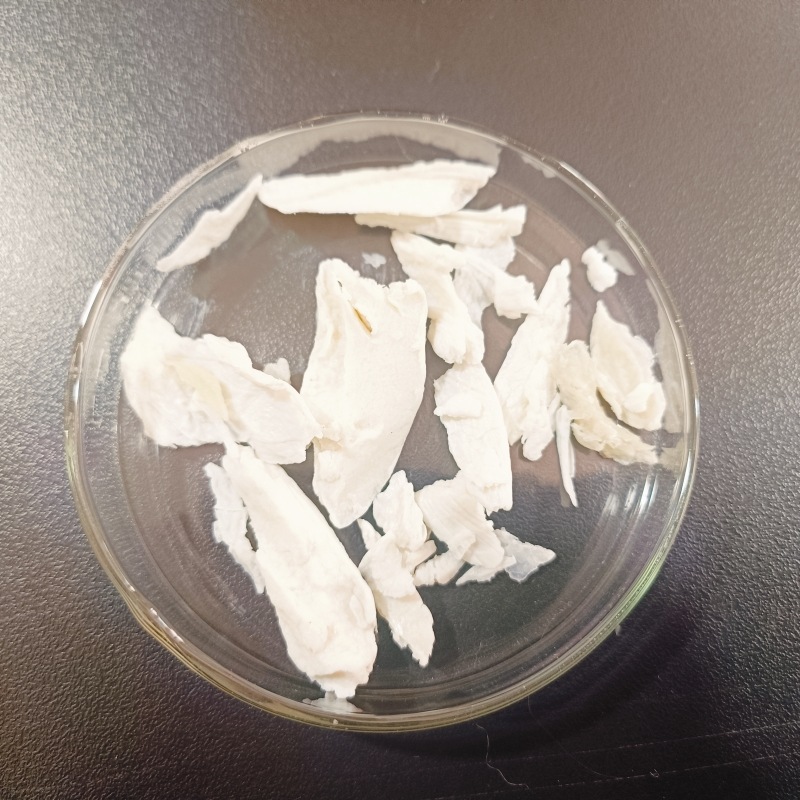

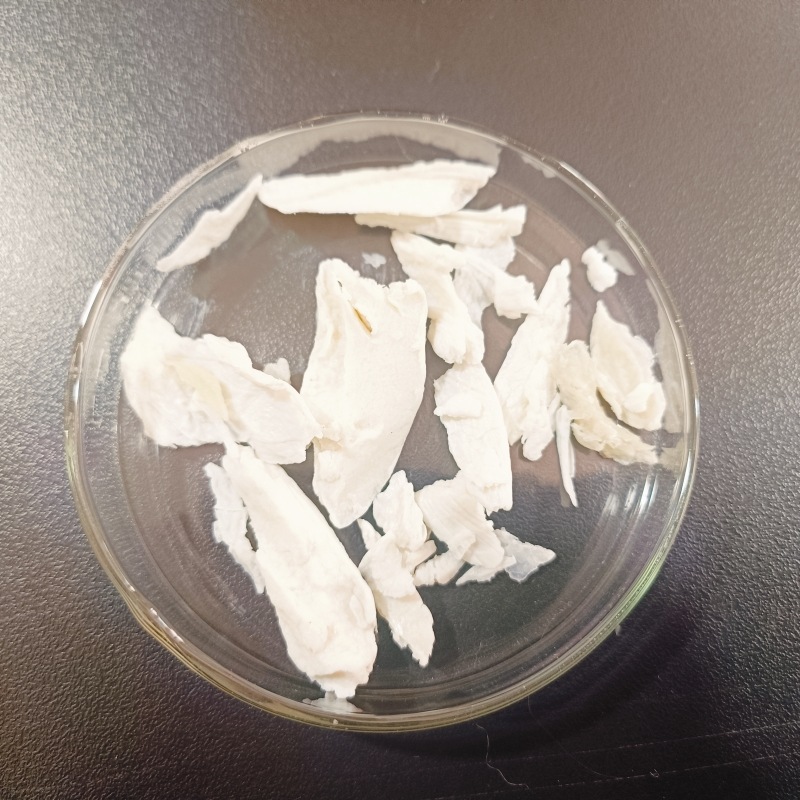

A block rubber sheet release agent functions as an essential barrier between the mold surface and rubber substrate, preventing adhesion and enabling smooth extraction of cured rubber sheets. Beyond basic release functionality, a high-performance block rubber sheet release agent must protect mold integrity, reduce friction-induced damage, and accommodate diverse elastomer types and molding conditions. With the global rubber sheet market in China alone poised to surpass 1.35 trillion yuan in 2025, the need for reliable, efficient block rubber sheet release agent solutions has never been more pressing.

Application Versatility Across Rubber Sheet Segments

Its versatile formulation adapts to the full spectrum of rubber sheet production needs, making it a universal solution for diverse industries:

●Automotive Sector: Ideal for manufacturing low-roll resistance rubber sheets used in new energy vehicle tires, where surface smoothness and dimensional precision are non-negotiable. This solution ensures consistent quality while supporting the automotive industry’s sustainability goals.

●Industrial Components: Used in producing high-strength rubber sheets for gaskets, seals, and machinery parts, this specialized release solution accommodates both natural and synthetic elastomers, including EPDM and nitrile rubber.

●Construction and Infrastructure: For heavy-duty rubber sheets used in waterproofing and vibration dampening, its weather-resistant film maintains performance even in harsh construction site conditions.

●Medical and Consumer Goods: This release agent’s non-toxic, residue-free formulation meets FDA standards for indirect food contact and medical device components, expanding its utility to high-regulation sectors.

Early adopters have reported transformative results. A leading industrial equipment manufacturer noted a 33% reduction in release agent consumption and a 20% increase in production throughput after switching to Shenyang Longgreen’s solution. Another customer in the automotive rubber components sector achieved a 15% drop in overall production costs, attributed to fewer defective sheets, extended mold life, and reduced labor for mold cleaning.

These outcomes align with broader market trends: as the global rubber sheet market shifts toward high-performance, eco-friendly products, the block rubber sheet release agent is well-positioned to capture growing demand. With China accounting for 35% of global rubber consumption, Shenyang Longgreen’s localized R&D and manufacturing capabilities enable rapid response to regional customer needs while supporting international expansion into Southeast Asian and African markets.

Future Innovation: Advancing Massive Rubber Sheet Demolding Agent Technology

Building on the success of its current product, Shenyang Longgreen is investing in next-generation developments focused on three key areas:

①Intelligent Formulations: Integrating sensor-compatible additives that enable real-time monitoring of release agent film integrity, allowing predictive maintenance and further reducing downtime.

②Biobased Ingredients: Developing a plant-derived block rubber sheet release agent to meet rising demand for circular economy solutions, with a target of 70% renewable content by 2026.

③Customized Solutions: Expanding the block rubber sheet release agent product line to address niche applications, such as high-temperature silicone rubber sheets and conductive rubber sheets for electronics.

Conclusion: A New Standard for Rubber Sheet Manufacturing

Shenyang Longgreen Science & Technology Co., Ltd.’s innovative block rubber sheet release agent represents a pivotal advancement for the global rubber industry. By combining superior performance, environmental responsibility, and application versatility, the block rubber sheet release agent addresses the critical needs of modern manufacturers while aligning with long-term sustainability goals. As the rubber sheet market continues its expansion, the block rubber sheet release agent stands as a testament to Shenyang Longgreen’s commitment to driving progress through technology and customer-centric innovation.

For manufacturers seeking to enhance efficiency, reduce costs, and elevate product quality, the new block rubber sheet release agent from Shenyang Longgreen offers a proven, future-ready solution—solidifying its role as an essential partner in the global rubber supply chain.