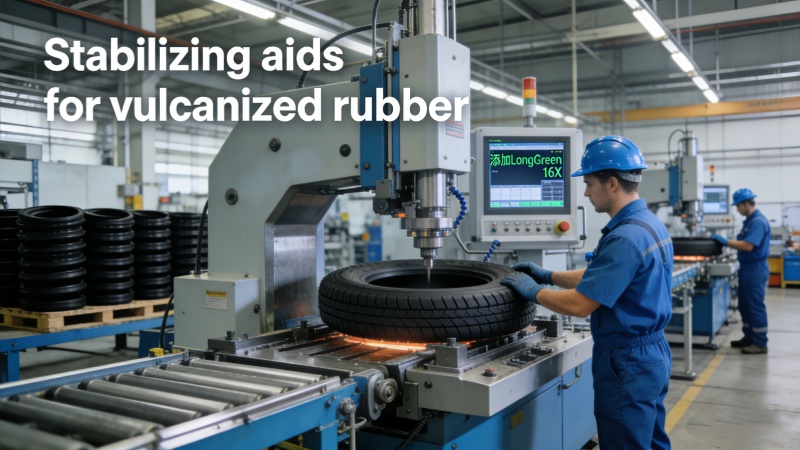

As professional stabilizing aids for vulcanized rubber, LongGreen 16X boasts exceptional multifunctional properties. It significantly enhances the flow performance of polymeric compounds by reducing viscosity and promoting slippage at the rubber-to-metal interface, enabling higher extrusion rates, improved dimensional stability, and consistent die swell—critical advantages for mass production of precision rubber parts. For injection moulding, especially with complex geometry moulds, the product optimizes mould flow, prevents sticking to metal surfaces, and ensures smooth demoulding without mould fouling—key strengths that make these stabilizing aids for vulcanized rubber indispensable in industries requiring intricate component manufacturing.

The product’s versatility shines through its wide-ranging specific application areas. It is ideally suited for automotive components (including tire sidewalls, engine seals, brake hoses, and suspension bushings), industrial machinery parts (such as conveyor belts, hydraulic seals, and vibration-damping pads), construction materials (waterproofing membranes, building expansion joints, and roofing rubber sheets), electronics accessories (shock-absorbing rubber gaskets for devices and insulation components), and specialty rubber products (medical-grade seals, marine anti-corrosion hoses, and aerospace rubber parts). These applications leverage LongGreen 16X’s properties to meet strict performance, durability, and safety standards.

Packaged in 25 kg plastic bags, LongGreen 16X has a 3-year shelf life when stored in closed containers under cool, dry conditions. As trusted stabilizing aids for vulcanized rubber, they reflect Shenyang LongGreen’s commitment to delivering accurate, credible solutions—backed by dedicated technical support to address sector-specific application needs.