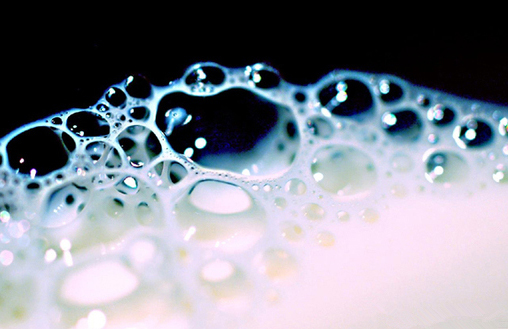

Introduction of Water Based Defoamer:

LongGreen 0610 water defoamer agent is a high-efficiency additive product developed based on a variety of imported foreign raw materials. Water defoamer agent can be used in a variety of water-based dispersion systems, can effectively control foam during flow and spraying, and has efficient defoaming capabilities in a lower concentration range. The water-based dilutable water defoamer agent contains 10% of silicone emulsion active ingredients, which are designed to control foam in aqueous systems. Water defoamer agent utilizes water as a carrier or continuous phase. By using water as a carrier and presenting these active ingredients in an emulsified form, these defoamers can be more easily dispersed in water and water-based process media and effectively suppress foam.

Advantages of Water Based Defoamers:

Water based defoamers are less expensive, water is the least expensive ingredient to add to a formulation, and water based defoamers can sometimes be made from byproducts of other manufacturing applications, making them cheaper and easier to produce. Effective water based defoamers can be diluted to lower concentrations with minimal production equipment, making them easier to use. Effective water based defoamers are easily dispersed in water and water-based solutions to suppress foam and degas. In addition, effective water based defoamers generally do not form deposits that can cause equipment failure, product damage or quality issues. Effective water based defoamers are suitable for a variety of industries and operations from paper processing to industrial process water to wastewater treatment.For optimal foam control, the water defoamer agent must be completely dispersed in the foam medium.

Follow these Steps to Achieve Complete Dispersion:

1. Stir the water-based defoamer before use.

2. Pre-dilution with 3-10 parts water to facilitate dispersion. Add the defoamer to the water and stir slowly. The pre-diluted material should be used immediately. If the defoamer can be dispersed by stirring sufficiently, it can also be added directly without pre-dilution.

3. If possible, add the defoamer to the location where the foam is generated in the system. 0610 Defoamers also contain ingredients that inhibit the growth of microorganisms. Dilution will reduce its inhibitory effect on microbial growth. If the diluted material needs to be stored for more than 7 days, inhibition needs to be added.

Why Choose Us?

Our products cover rubber release agents for tire rubber mixing processes (powder, paste, block, liquid), rubber release agents for vulcanization processes (tire inner tube paint, tire outer tube paint, release agent, marking), tire inspection tools (dynamic balancing lubricant, marking roller), and the service scope covers more than 30 provinces and cities across the country, providing timely and complete pre-sales and after-sales services. Welcome your consultation!