Introduction of Non-marking Rubber Mold Release Agent:

Non-marking rubber mold release agent is a mold release agent designed for rubber product vulcanization process, with lubrication and brightening functions. Non-marking rubber mold release agent has a milky white viscous liquid appearance, a pH value of 5.0-8.0, and is suitable for a variety of coating methods. The unique formula of Non-marking rubber mold release agent ensures efficient demoulding while taking into account environmental protection and ease of operation, making it an ideal choice for industrial production.

Features of Highly Efficient Rubber Mold Release Agent:

Highly efficient rubber mold release agent is easy to operate and can be sprayed, brushed or dipped. It can be diluted as needed (recommended ratio 1:2, low hardness water). Highly efficient rubber mold release agent emulsion is relatively stable. If it is unopened and stored in a cool and dry place below 35°C, the product has a shelf life of 12 months from the date of production. Highly efficient rubber mold release agent has a wide range of uses and is suitable for rubber, plastics, textiles, automobiles, furniture and other fields. Highly efficient rubber mold release agent products have high demoulding efficiency. Even when the amount used is small, efficient demoulding can be achieved, ensuring that each mold can maintain a perfect appearance and reducing the workload of cleaning and maintenance. The freeze-thaw stability of Highly efficient rubber mold release agent has been verified through six cycles and can still maintain excellent performance and can adapt to various environmental changes.

Application of Release Agent for Rubber Article Vulcanization:

Release agent for rubber article vulcanization can be used as a release agent and lubricant. The product is efficient, stable and widely used.

1. Non-marking rubber mold release agent is suitable for vulcanization demoulding of rubber and plastic products, such as brake pads, screw heads, plugs, etc., to ensure that the surface of the product is smooth and traceless.

2. In the lubrication of extruded rubber products such as conveyor belts, it can effectively reduce friction. At the same time, Non-marking rubber mold release agent is also widely used in the textile industry, such as lubrication of yarn, sewing needles, socks and underwear production, to improve the smoothness and efficiency of the production process.

3. Non-marking rubber mold release agent can be used as an important component of automotive and furniture brighteners to provide efficient gloss protection for the surface. In addition, in the lubrication and protection of glass fiber filters, it can effectively extend the service life of equipment.

4. Release agent for rubber article vulcanization can also be used as a brightener component for other purposes and is compatible with most other silicone emulsions.

Precautions:

1. Wear protective glasses during operation to avoid contact with eyes; if accidentally contacted, rinse immediately with plenty of water.

2. Users should conduct a small test before production to determine the optimal concentration. The dilution ratio is 1 part product plus 2 parts low-hardness water.

3. Store sealed in a cool and dry place (≤35°C), avoid direct sunlight, and the shelf life is 12 months.

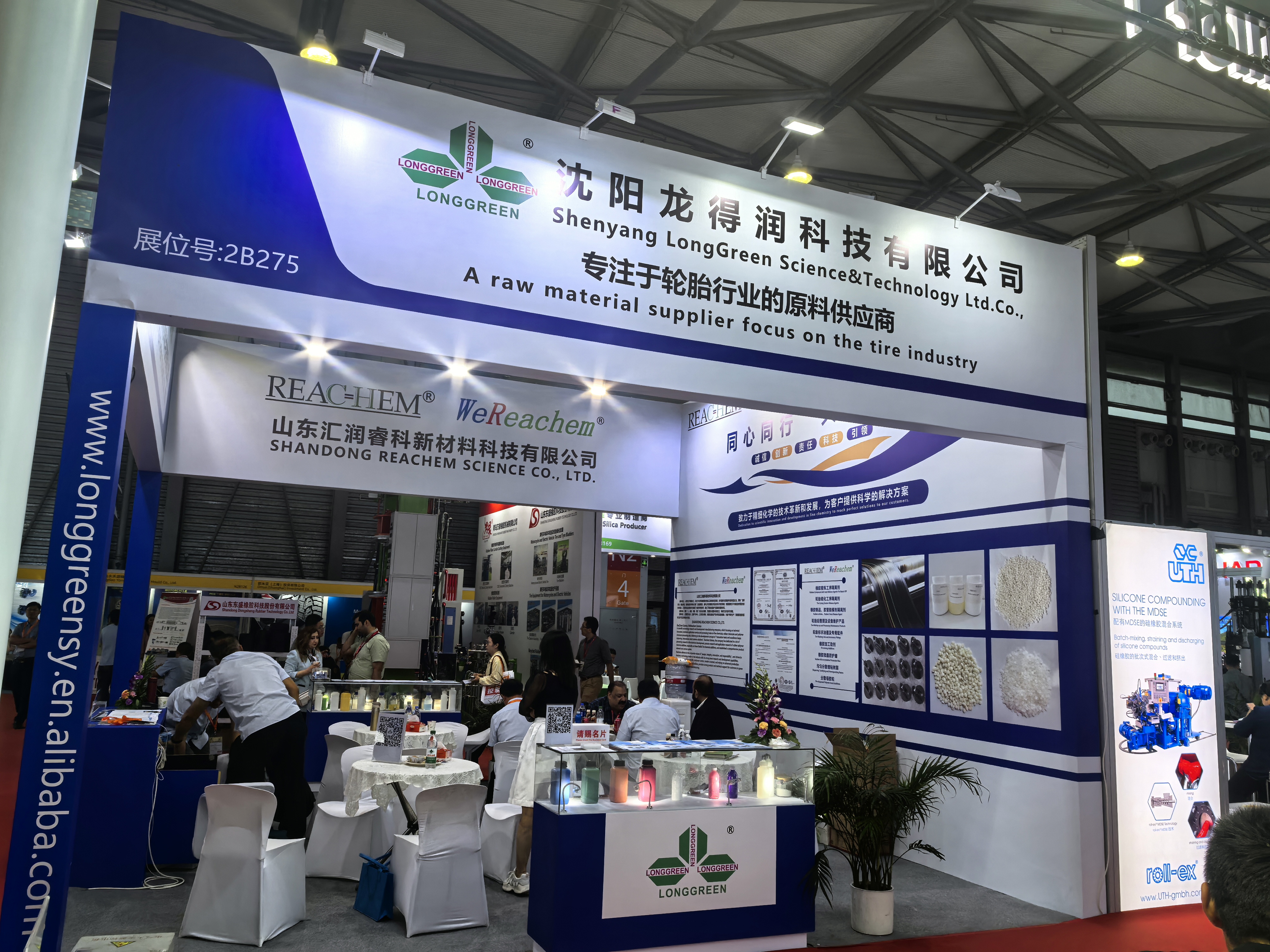

About Us:

Shenyang LongGreen Science & Technology Co., Ltd. is a high-tech enterprise based in the field of release agents and rubber additives, providing environmentally friendly release agents, rubber additives and related services. The company was established in 2011 and is a high-tech enterprise come out from the garage. Our company has decades of experience in the rubber release agent and rubber additive industry, and relies on technical experts in rubber release agents and rubber additives to continuously optimize and innovate technology, providing customers with customized products and services to meet customer needs.